Understanding Camshaft Design: A Comprehensive Guide

Camshafts are a fundamental component of an engine’s operation, yet their design remains a mystery to many. In this comprehensive guide, we will delve into the intricate world of camshaft design. From understanding the basics to exploring advanced concepts, we will leave no stone unturned. Buckle up, as we embark on a journey to demystify the intricacies of camshaft design.

The Role of Camshafts in Engine Performance

Before we dive into the intricacies of camshaft design, let’s first understand the fundamental role camshafts play in an engine’s performance.

Camshafts are the heart of an engine’s valvetrain system. They are responsible for regulating the opening and closing of intake and exhaust valves in an internal combustion engine. This vital function directly impacts an engine’s power, torque, and overall efficiency.

Key Takeaway: Camshafts are the unsung heroes behind your engine’s performance, controlling when and how valves open and close.

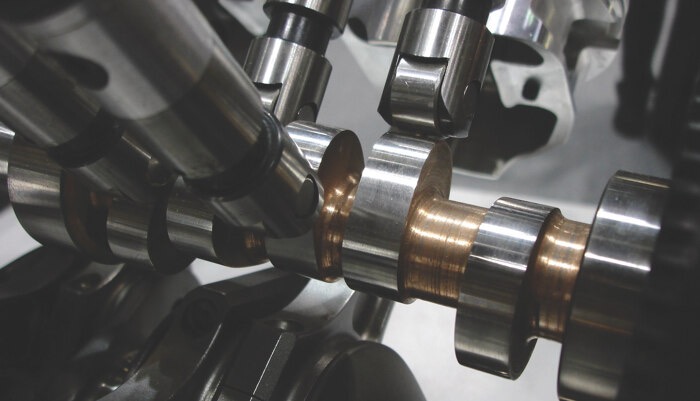

Anatomy of a Camshaft

To understand camshaft design, we must first dissect its anatomy. A typical camshaft consists of several crucial components:

- Cam Lobes: These are the raised, egg-shaped sections that dictate the valve’s motion. Cam lobes come in various shapes and sizes, influencing valve timing and lift;

- Journal Bearings: These support the camshaft, allowing it to rotate smoothly within the engine. Proper lubrication is essential to prevent wear and friction;

- Timing Gear: The timing gear connects the camshaft to the crankshaft, ensuring synchronized operation;

- Core Material: Camshafts are typically made from high-strength materials like cast iron, steel, or even lightweight alloys for performance applications.

Camshaft Profiles: The Heart of Design

One of the most critical aspects of camshaft design is the cam profile. This profile determines how the valves open and close, directly impacting engine performance. Let’s explore some common camshaft profiles:

Flat-Tappet Camshafts

Flat-tappet camshafts have a smooth and constant cam lobe shape, making them a popular choice for various engines. Here’s a closer look at their characteristics:

- Smooth Lobe Shape: These camshafts feature a consistent lobe shape that provides stable valve operation;

- Usage in Older Engines: Flat-tappet camshafts are commonly found in older engines, known for their simplicity and cost-effectiveness;

- Suitable RPM Range: They are suitable for low to mid-range RPM applications, making them ideal for everyday vehicles and industrial machinery.

Roller Camshafts

Roller camshafts represent a significant advancement in camshaft technology, particularly in high-performance engines. Let’s examine their attributes:

- Roller Follower: Roller camshafts feature a roller follower that reduces friction and wear, resulting in smoother valve operation;

- High-Performance Benefits: These camshafts are ideal for high-performance engines due to their ability to handle higher RPMs, allowing for increased power output;

- Precision Engineering: Roller camshafts require precise engineering to ensure longevity and consistent performance, making them a top choice for racing applications.

Hydraulic vs. Solid Lifters

The choice between hydraulic and solid lifters is a critical decision in camshaft design. Here’s a comparison of the two lifter types:

- Hydraulic Lifters: Hydraulic lifters use a hydraulic mechanism to maintain valve lash and reduce maintenance requirements. They are known for their quiet operation and ease of use. However, they may not be suitable for high-revving engines;

- Solid Lifters: Solid lifters have no hydraulic components and are typically used in high-performance engines. They offer precise valve control but require regular maintenance to adjust valve lash.

Pro Tip: The choice of cam profile is crucial and depends on your engine’s intended use and performance goals. Consider factors like RPM range, application, and maintenance requirements when making your decision.

Materials Matter: Camshaft Construction

The choice of materials significantly impacts a camshaft’s performance and longevity. Camshafts are crafted from a variety of materials, each with its own unique characteristics and suitability for different applications.

Cast Iron

Camshafts made from cast iron are celebrated for their durability and remarkable resistance to wear. This makes them a preferred choice for use in everyday vehicles and industrial applications. Additionally, cast iron camshafts are cost-effective, offering a balance between performance and affordability, making them a reliable choice for applications where extreme performance is not the primary concern.

Steel

Steel camshafts find favor in the world of performance and racing applications. The allure of steel lies in its exceptional strength-to-weight ratio. This material is capable of withstanding the high stresses associated with high-performance engines. Moreover, steel camshafts demand precision machining to ensure smooth operation and durability under the most demanding conditions.

Aluminum Alloys

Camshafts constructed from aluminum alloys cater to the needs of high-revving, high-performance engines where weight reduction plays a pivotal role. Their lightweight nature contributes to improved engine responsiveness and overall performance. However, their use necessitates precise engineering to ensure longevity and reliability.

Enthusiasts seeking maximum power often gravitate towards aluminum alloy camshafts.

Fun Fact: Camshafts are subjected to extreme conditions, including intense heat and stress.

Therefore, the selection of the appropriate material is paramount to ensure optimal performance and longevity.

Camshaft Design Considerations

Designing a camshaft is a multifaceted process that encompasses a range of critical considerations. These considerations are vital in determining how a camshaft will influence engine performance and behavior.

Valve Overlap

Valve overlap is a pivotal factor that exerts a profound influence on engine efficiency and emissions. This phenomenon occurs during the brief period when both the intake and exhaust valves are partially open. The design of valve overlap has a direct impact on cylinder pressure, emissions levels, and the overall performance of the engine.

Duration and Lift

The duration and lift of the camshaft lobes play a pivotal role in shaping an engine’s powerband and torque curve. Longer duration and higher lift profiles tend to favor increased high-end power, allowing engines to deliver more horsepower at higher RPMs. Conversely, shorter duration and lower lift profiles optimize low-end torque, enhancing low-speed performance.

Phasing

Camshaft phasing involves the precise adjustment of the camshaft’s timing relative to the crankshaft. This optimization is instrumental in enhancing engine performance by fine-tuning valve timing for various operating conditions. The outcome is improved power delivery and enhanced fuel efficiency, making phasing a critical consideration in camshaft design.

Performance vs. Efficiency

Camshaft design often necessitates striking a delicate balance between achieving maximum power and maintaining fuel efficiency. High-performance camshafts may prioritize increased power output at the expense of fuel efficiency. On the other hand, economy-focused camshafts aim to enhance fuel economy while sacrificing some performance.

Lightpipe Camshaft Design: Revolutionizing Performance

In the dynamic realm of camshaft design, one innovation stands out: lightpipe camshafts. These cutting-edge components blend advanced materials and precision engineering to redefine how camshafts influence engine performance.

Advantages of Lightpipe Camshafts:

- Material Advancements: Lightpipe camshafts employ high-strength composites and specialized alloys, offering unmatched durability while reducing weight;

- Weight Reduction: By shedding excess weight, lightpipe camshafts enhance engine responsiveness, benefiting both power and fuel efficiency;

- Precision Engineering: These camshafts are crafted with meticulous precision, ensuring accurate valve timing and optimal performance.

Performance & Efficiency: Lightpipe camshafts boost power output and improve fuel efficiency, making them a game-changer for both performance enthusiasts and eco-conscious drivers.

Conclusion

In this comprehensive guide, we’ve peeled back the layers of camshaft design, uncovering the secrets that drive engine performance. From understanding camshaft profiles to exploring advanced technologies, you are now equipped with the knowledge to make informed decisions about camshaft design for your specific application.

Leave a Reply