The chassis of a vehicle serves as the framework, housing, and support system for all its components, impacting the vehicle’s performance, safety, and structural integrity. Let’s explore the diverse world of chassis design, delving into various types, structural frameworks, and crucial considerations in creating an efficient and robust chassis for automobiles.

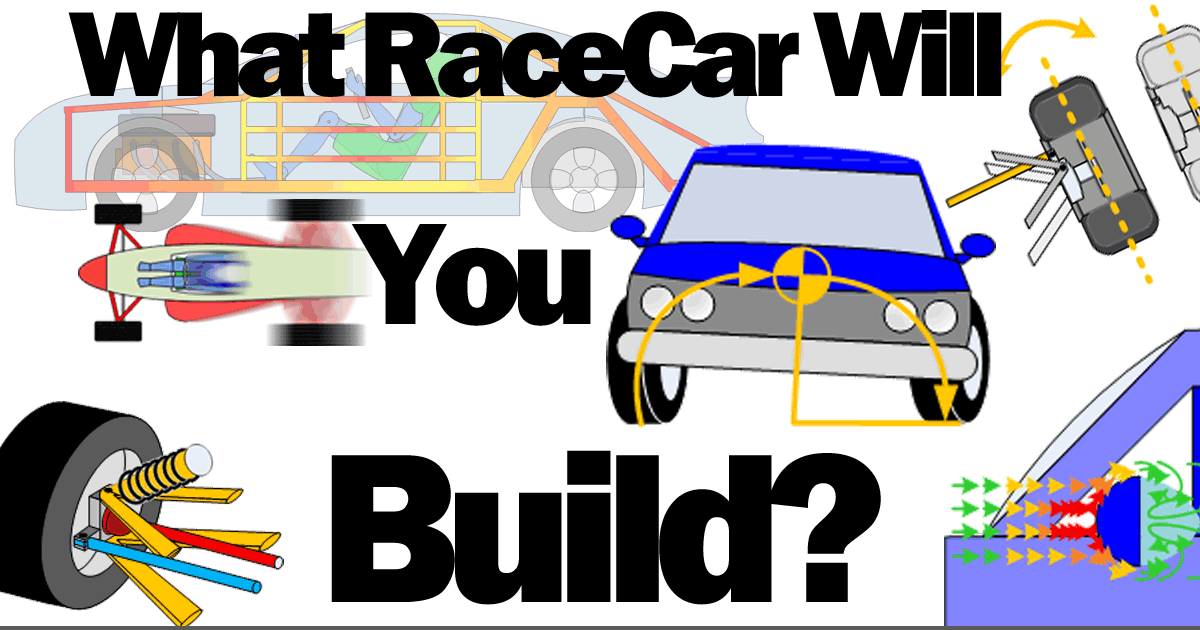

Chassis Types

Automobile chassis can be broadly categorized into two main types: spaceframe and monocoque. These variations utilize distinct approaches in constructing the vehicle’s foundation and have their unique advantages and limitations. Understanding these distinctions is pivotal in designing an optimal chassis for specific automotive applications.

Spaceframe Chassis

The spaceframe chassis employs an intricate arrangement of cut and shaped metal tubing, forming a durable framework that emphasizes strength and rigidity. Triangulation, a core principle in spaceframe design, plays a crucial role in fortifying the structure against deformation and enhancing its load-bearing capabilities.

Triangulation in Spaceframe Design

Triangulation is pivotal in reinforcing the spaceframe structure, ensuring its resistance to external forces. By strategically incorporating triangulated tubes, the chassis gains substantial strength, mitigating vulnerabilities associated with tension and compression.

Compression and Tension in Spaceframes

Understanding how spaceframe structures handle compression and tension is imperative. While tension-loaded members offer superior strength, those subjected to compression demand meticulous consideration in material choice and gauge to avert potential buckling issues.

Monocoque Chassis

In contrast, the monocoque chassis presents an evolved design paradigm where a panel acts as the structural foundation. This innovation redistributes forces efficiently, showcasing superior tension load-handling capabilities while presenting challenges in compression resistance.

Comparing Monocoque and Spaceframe Behavior

Evaluating the behavior of these chassis types under varied loads elucidates their contrasting responses. While monocoque excels in tension handling, spaceframes showcase limitations in compression resistance. Each possesses distinct advantages, underscoring the significance of meticulous design considerations.

Torsional Rigidity

Torsional rigidity, an essential property of a vehicle’s chassis, governs its stability against twisting forces. A highly rigid chassis ensures predictable handling by minimizing unwanted chassis flex, enhancing suspension efficiency, and optimizing overall vehicle performance.

Chassis Design Tips

Practical insights into chassis modification, model-building techniques, and the significance of planning chassis design around suspension components are fundamental considerations. Visualizing load paths and optimizing the center of gravity are paramount in creating a well-balanced and efficient chassis.

Explore more in this in-depth article

Which Chassis Type to Choose?

The decision between spaceframe and monocoque chassis hinges on complexity, detection of damages, and overall manageability. While novice designers often opt for spaceframes due to ease in design and operation, the complexity of monocoque design offers a rewarding learning curve and extensive engineering applications.

Layout Optimization for Access and Maintenance

Strategic tube placement for rigidity should also account for convenient access during maintenance and repairs. A well-thought-out design ensures easy access to critical components without compromising structural integrity, facilitating quick repairs and component replacements.

Studying Competitive Vehicles

Analyzing high-performance vehicles in your class can offer valuable insights into effective chassis designs, materials, and construction methods. Observing these successful models both on and off the track can illuminate key factors contributing to their performance.

Tube Shape and Size Optimization

Selecting optimal tube shapes and sizes based on specific structural requirements is crucial. The type of load, whether in tension or compression, determines the appropriate gauge, size, and material to optimize strength-to-weight ratios, impacting chassis performance significantly.

Material Selection: Steel, Aluminum, and Composite

Materials like steel, particularly 1018, 1020, or 4130 chromoly, serve as popular choices for their balance of strength, durability, and ease of fabrication. Aluminum offers weight-saving advantages but requires meticulous consideration due to its welding and fatigue characteristics.

For monocoque designs, fiber reinforced plastics (FRP) like fiberglass or carbon fiber offer lightweight, high-strength alternatives.

Structural Shapes: Flexibility and Strength

Structural shapes like square or rectangular tubing enable easier fabrication and welding. Circular tubing, although more complex to work with, provides higher strength and reduced weight, particularly when using 4130 chromoly.

Oval tubing, preferred in open-wheel race cars for its aerodynamics, balances weight and structural strength, despite limitations in certain load-bearing aspects.

Considering the Right Material and Construction Complexity

Weight, fabrication ease, and repairability guide material choices. Mild steel remains a standard due to its welding characteristics and durability. For weight-conscious designs, 4130 chromoly provides strength with reduced weight, albeit with more complex fabrication needs.

Exploring Structural Shapes: Square and Rectangular Tubing

Square and rectangular tubing offer straightforward fabrication and welding advantages. They provide ease in creating box-like structures and are favored for their simplicity in joining and construction. The rectangular form allows designers to create a beam-like structure, providing enhanced strength along one axis, ideal for varied load-bearing requirements.

Circular Tubing: Strength and Complexity

Circular tubing, while more intricate to work with, is available in high-strength options like 4130 chromoly. Its inherent strength-to-weight ratio makes it a preferred choice where weight reduction without compromising structural integrity is crucial. However, due to the complexities in fabrication and welding, circular tubing may require specialized tools and techniques.

Learn about the role of aerodynamics in advancing suspension design software

Oval Tubing: Aerodynamics vs. Structural Strength

Oval tubing finds its niche in open-wheel race cars due to its aerodynamic advantage over other shapes, reducing drag and turbulence. While it offers aerodynamic benefits, it may lack the structural strength of round or square tubing, especially along the narrower dimension.

I-Beam Structural Shape: Minimizing Deflection

The I-Beam configuration serves well when minimizing deflection along the vertical axis is crucial. In scenarios with long spans, I-Beam structures demonstrate superior resistance to bending or deflection compared to square tubing. However, its use is specialized and depends on specific load requirements.

Structural shapes in chassis design significantly impact the overall strength, weight, and handling characteristics of a vehicle. Each shape bears its advantages and limitations, influencing decisions based on load-bearing necessities, fabrication complexity, and performance goals. The choice of shape often hinges on a delicate balance between structural needs and fabrication ease.

Recommendations for Optimal Chassis Design:

- Material Selection Precision: Choose materials wisely, factoring in strength, weight, and welding ease. For spaceframes, steel grades like 1018 and 1020, or 4130 chromoly for higher strength, are ideal. Monocoques often use fiber reinforced plastic (FRP) for its weight-saving properties;

- Shape Optimization: Tailor the structural shape to meet specific load demands. Square and rectangular tubing offer ease in fabrication, while circular tubing provides superior strength-to-weight ratios. Oval tubing suits aerodynamic considerations, and I-Beam shapes minimize deflection in elongated spans;

- Torsional Rigidity: Prioritize torsional rigidity to enhance predictability and stability. Rigorous testing and analysis using methods like Finite Element Analysis (FEA) can fine-tune chassis designs for optimal performance;

- Maintenance Accessibility: Design chassis layouts that facilitate easy access for maintenance and repairs. Ensure vital components are reachable without compromising the chassis’s structural integrity.

Conclusion

Chassis design is the backbone of vehicle performance, determining its strength, durability, and handling dynamics. The careful selection of materials, thoughtful consideration of structural shapes, and precise design techniques all culminate in crafting an optimal chassis.

Whether favoring the simplicity of square tubing or the aerodynamic advantage of oval shapes, every design choice contributes to the chassis’s overall performance and reliability on the track.

By meticulously balancing strength, weight, and practicality, engineers can create chassis that not only withstand the rigors of racing but also offer precision, agility, and utmost safety, enhancing the driving experience and pushing the boundaries of automotive excellence.