Cars Sketch Design: Creativity in Automotive Engineering

In the intricate and innovative world of automotive design, the role of car sketch design is both foundational and transformative. This creative process, though representing a relatively small portion of the overall cost in automotive model development, is a critical determinant of a car’s final market performance. Let’s embark on a detailed exploration of the steps and nuances that define this fascinating journey from concept to reality.

Step One: From Product Planning to Modeling Positioning

The genesis of automotive design lies in thorough market research. This stage is critical for understanding the competitive landscape and identifying potential niches for new models. Designers and planners analyze various factors such as pricing strategies, target customer demographics, competing models, and prevailing design trends. These insights are essential in defining the style and functional positioning of the new model, ensuring its relevance and appeal to the intended market segment.

A significant aspect of this initial phase is the general layout design. Here, designers make preliminary decisions about the arrangement of various car parts and the seating posture of occupants. This layout must satisfy functional space requirements while adhering to ergonomic standards, balancing the need for comfort and practicality.

Step Two: From Sketch to Effect Diagram

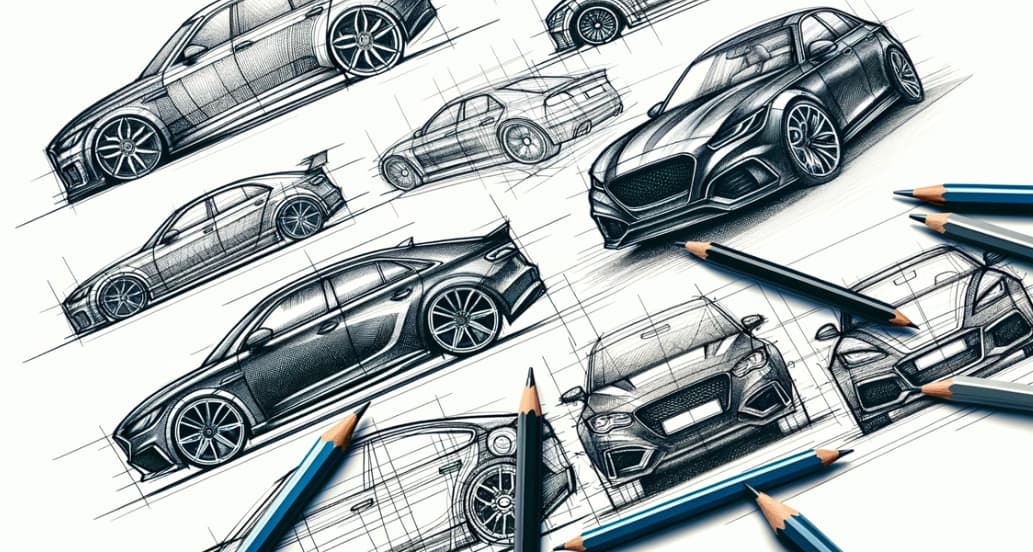

The second phase is where imagination begins to take a tangible form. Designers transform their initial ideas into sketches and effect diagrams. These two-dimensional representations are the first visual embodiments of the future car, showcasing innovative ideas that distinguish the model in a competitive market. Given the typically long development cycle of a car, which can range from 18 to 48 months, these initial designs must be forward-looking, anticipating market trends well into the future.

Sketching is an immediate and powerful method of expressing a designer’s creative vision. These sketches are often informal yet rich in originality, capturing unique concepts that could define the car’s character. Following the sketching phase, an internal review process selects several promising designs for further refinement into effect diagrams.

Effect diagrams are more than just refined sketches; they serve as critical guides for the subsequent creation of clay and digital models and are essential for project presentations. These diagrams need to accurately depict proportions, perspectives, colors, and materials. At this stage, the unrestricted creativity of the sketches is refined and shaped by practical considerations such as market aesthetics, cost, regulatory requirements, material technology, and more.

Step Three: Three-dimensional Model

While effect diagrams offer a glimpse into the envisioned car, they fall short in capturing every nuance. The creation of a three-dimensional (3D) model addresses this gap, providing a more concrete and detailed representation of the design. This model comes in various forms, including solid models like small-scale clay models, full-size clay models, resin models, and digital models. Each type serves a specific purpose in the design refinement process.

The small-scale models, typically at 1/4 or 1/2 scale, offer a more accurate sense of size and proportion compared to effect diagrams. Creating these models requires a painstaking focus on every line and surface. Some leading design firms use advanced 3D modeling software to create a mathematical model of the car, which is then used to mill out a clay model with CNC machines. This model is then meticulously finished by hand.

Once several small-scale models are completed, they undergo a formal review to determine the preliminary design direction. This leads to the creation of a full-size (1:1) model, an essential step in refining the design. A full-size clay model, as the same size as the actual vehicle, offers an unmatched level of detail and realism, providing invaluable insights for the designers.

Step Four: Automotive Prototyping

After the A-class model is finalized, a hard model prototype is created. This prototype is as close as possible to the final automotive product and undergoes various iterative design modifications. This stage is crucial for refining the design and ironing out any practical issues. A range of prototyping technologies is employed, including 3D printing, CNC machining, vacuum casting, and rapid tooling. These technologies facilitate different aspects of the prototyping process, such as engineering verification, functional testing, pre-production, and market testing.

Conclusion

The automotive design process does not end with the launch of the car. User feedback post-launch often leads to further refinements in the design. Advances in technology, such as paperless and clay-free design, are continually reshaping the automotive modeling process. However, the core skills required of automotive designers remain constant. Observation, imagination, aesthetic sensibility, spatial awareness, engineering knowledge, social science understanding, practical skills, and a sense of responsibility are all essential attributes for success in this field.

In sum, car sketch design is a complex, multifaceted process that blends art, science, and technology. It is about envisioning the future, harnessing technological advancements, and capturing the spirit of mobility in every design decision. This process defines not just the aesthetic appeal of a vehicle but also its functionality, marketability, and ultimate success in the competitive automotive market. The journey from an initial sketch to a market-ready car is a testament to the creativity, skill, and foresight of automotive designers, who play a pivotal role in shaping the future of transportation.

Leave a Reply