Introduction to Scratch-Built Stock Cars

Scratch-built stock cars, often likened to “Late models” or “NASCAR” vehicles, are custom-designed racing cars that resemble standard production cars but are constructed using a tube chassis instead of a traditional unibody frame. Originating from modified production vehicles, these cars are now entirely custom-built for racing.

Key Features and Design Principles

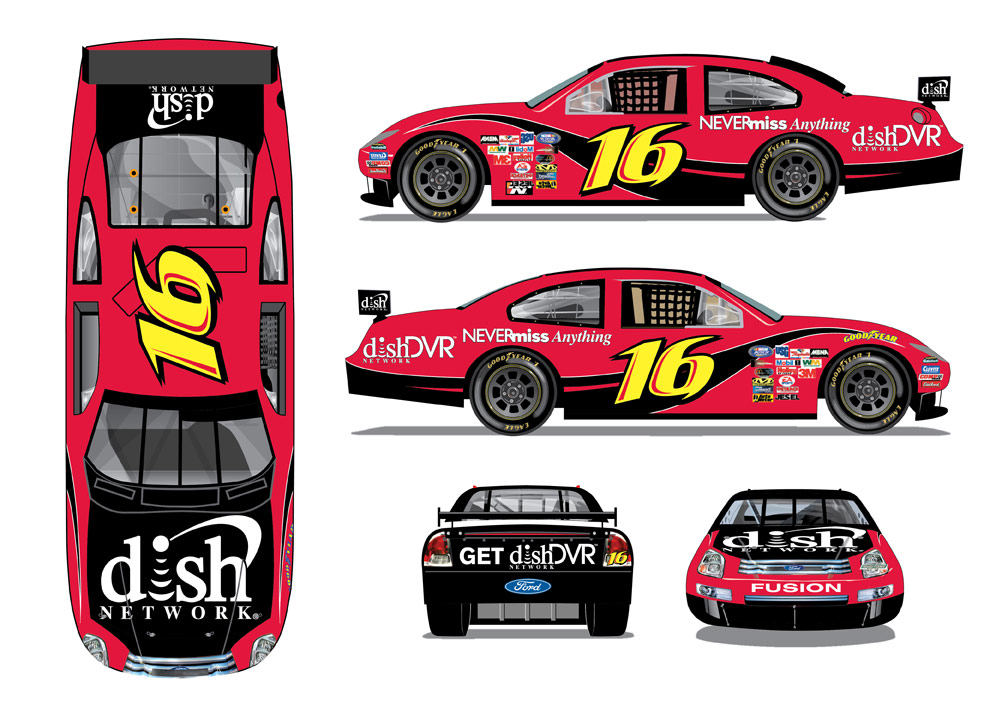

These vehicles are notable for their tube frame chassis and powerful front-mounted engines that drive the rear wheels. Designed for minimal ground clearance, they achieve a low center of gravity (CG) for optimal handling. The bodywork, crafted from steel or FRP composites, mimics the appearance of production cars but is tailored for racing efficiency.

Detailed Design and Construction Process

Comprehensive knowledge of handling, chassis, suspension, powertrain, aerodynamics, and safety is crucial. The interplay of these components requires a holistic approach to ensure a harmonious and optimized design.

Specialized Challenges in Design

- Weight Distribution: Achieving an almost balanced front/rear weight distribution is key, considering the front-engine configuration;

- Suspension: Focus on maximizing tire contact through sophisticated suspension geometry, including an adjustable rear spring wedge for weight transfer;

- Chassis: Incorporating torsional rigidity to ensure predictable handling, balancing performance requirements with weight minimization;

- Powertrain: Optimal engine placement for balanced weight distribution, along with considerations for intake, cooling, and exhaust systems;

- Aerodynamics: Utilizing elements like front air dams and rear spoilers or wings for downforce, with an emphasis on dual-function airflow design for efficiency and speed.

Safety Considerations

Designing a robust safety cell with racing seats, harnesses, and padding is paramount, alongside fuel safety cells and integrated firewalls for comprehensive protection.

Understanding and Managing Construction Challenges

Constructing a stock car requires precision, especially in aligning the chassis and suspension. A well-equipped workshop is necessary, and metalworking skills are crucial. Utilizing jigs for chassis assembly and understanding the specific requirements of different metals is essential for a sound structure.

Financial Considerations in Building a Stock Car

The cost of building a stock car varies with the choice of components and desired competitiveness. Sourcing parts from racing suppliers or aftermarket companies can impact overall expenses, with the option to purchase pre-fabricated chassis as a cost-effective alternative.

Preparing for Racing: Costs and Logistics

Racing expenses include consumables like tires and fuel, as well as maintenance costs such as engine rebuilds and body repairs. Transportation logistics, primarily trailering, are also crucial aspects to consider.

Comparison Table: Traditional vs. Scratch-Built Stock Cars

| Feature | Traditional Stock Cars | Scratch-Built Stock Cars |

|---|---|---|

| Chassis | Modified production unibody | Custom tube frame chassis |

| Bodywork | Based on production cars | Formed steel or FRP composite |

| Suspension | Standard production-based | Custom-designed for racing |

| Powertrain | Production-derived engines | High horsepower, racing-optimized engines |

| Aerodynamics | Minimal modifications | Advanced aerodynamic components |

| Safety Features | Standard enhancements | Comprehensive, racing-specific safety cell |

Specialized Suspension Design for Stock Cars

The suspension system in a NASCAR-style stock car is a critical component, engineered to handle high speeds and maintain stability on various tracks. Key aspects include:

- Advanced Dampers and Springs: Customized to suit the specific demands of each track, providing optimal grip and stability;

- Geometry Tuning: Precise adjustments to the suspension geometry for better handling and responsiveness, particularly important in oval track racing;

- Weight Transfer Management: Designing the suspension to manage weight transfer efficiently during acceleration, braking, and cornering;

- Durability: Ensuring that the suspension can withstand the rigors of racing, including the impacts and stresses encountered on different tracks.

Conclusion

In conclusion, designing and constructing a NASCAR-style stock car is an elaborate and technically demanding process. It involves a deep understanding of automotive engineering principles and the ability to balance performance, safety, and cost considerations. This guide provides a comprehensive overview for enthusiasts and professionals who aspire to build high-performance racing vehicles, highlighting the unique aspects of scratch-built stock cars in contrast to traditional models.

Leave a Reply